Tech Briefs

Savannah River National Laboratory

Method of Trapping Zinc Vapor by Using Zinc Getter Materials

Researchers at the Savannah River National Laboratory (SRNL) have developed a process to successfully capture radioactive 65Zn during TPBAR extraction.

Background

Radioactive zinc vapors can deposit as solid 65Zn during nuclear processing, such as during the irradiation of extracted tritium-producing burnable absorber rods (TPBARs). An examination of the gloveboxes displayed the presence of zinc outside of the radiation protection areas. In order to prevent radioactive contamination, it is desirable to efficiently and effectively capture and trap radioactive metal vapors. Various physical and chemical methods of trapping and retaining zinc vapors have been employed; however, in certain instances, these methods use materials that may not exhibit the necessary thermal stability when used at high temperatures. As a result, they may not be as effective for trapping zinc vapors or they may display reversibility in zinc gettering activity. There is a need to provide an efficient method of trapping zinc vapors by employing zinc getter materials that are suitable for use at high temperatures.

At a glance

- Compact and portable

- Low costs and low maintenance

- Environmentally safe

- Minimizes radiation exposures

- Scalable for large volume operations

- Applications to radioactive Cd-109 and non-radioactive vapor sequestration in semiconductor industry and others

- U. S. Patent 9,700,829 B1

A Better Alternative

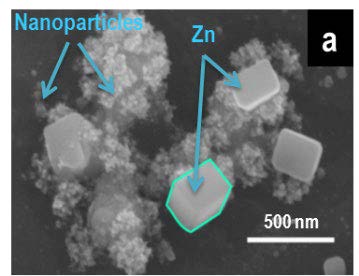

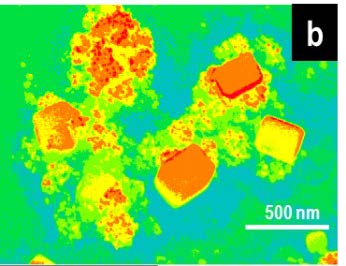

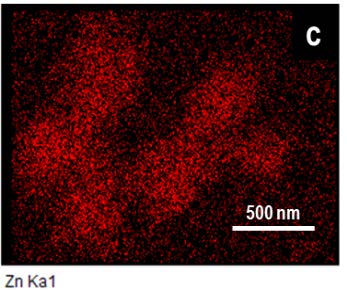

A zinc active nanomaterial (NM) support that can be used in the extraction process lid and keep the radioactive gamma emitting zinc in a high radiation area rather than in the glove boxes has been developed. This invention describes an advanced nanotechnology solution that can effectively capture and remove 65Zn during TPBAR extraction. Successful capture of radioactive zinc, 65Zn, in the furnace model will reduce costs and prevent product contamination by precluding a waste stream of contaminated filters. It will also reduce potential dose to the worker, enhancing ALARA goals by retaining the contaminant in an area that was designed for it. This concept, or a variation of it, may also be applicable to radioactive Cd, Cd-109, capture.

All metal items are unique at the microscopic level. They are made up of individual grains arranged in a unique pattern, much like a snowball is made up of individual snowflakes. Thanks to modern megapixel cameras, this unique grain structure can be photographed. At a later time when the container is being inspected for tampering, another photograph is taken. These are compared, any changes in the grain structure indicates tampering. Even if the bolt is removed and reinstalled, the deformation of the grain structure will be unique.

Stage of Development

This technology has been bench-scale tested. The nanoparticle-based getters exhibit improvements over bulk material getters.

The nanomaterial gettering system that has been developed is tailored to efficiently and irreversibly capture the highest amount of Zn-65 vapors over a wide range of parameters in the laboratory setting.

Additional work is underway to assess deployment conditions of the technology in the plant for efficient gettering capabilities.

Partnering Opportunities

SRNL invites interested companies with proven capabilities in this area of expertise to develop commercial applications for this process under a cooperative research and development agreement (CRADA) or licensing agreement. Companies interested in licensing will be requested to submit a business plan setting forth company qualifications, strategies, activities, and milestones for commercializing this invention. Qualifications should include past experience at bringing similar products to market, reasonable schedule for product launch, sufficient manufacturing capacity, established distribution networks, and evidence of sufficient financial resources for product development and launch.

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov