Tech Briefs

Savannah River National Laboratory

Method of Trapping Zinc Vapor by Using Zinc Getter Materials

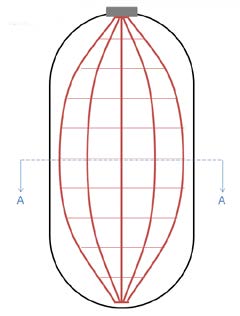

Savannah River National Laboratory (SRNL) is currently in the conceptual design stage of a bow-like expandable in-tank heat exchanger unit that can be inserted into a prefabricated vessel and expanded internally in order to minimize heat transfer paths. The heat transfer unit is designed such that it can slide through the vessel opening with a diameter smaller than that of the overall internal tank diameter. Once inserted into the vessel, a tension system can be either applied or released (heat exchanger frame defaulting to a straight or curved form, respectively) in order deploy the heat exchanger and expand it radially within the vessel. Using this expandable framework design, the heat exchanger unit can provide heating, cooling, and/or measurement capabilities within a prefabricated vessel without augmenting the vessel by utilizing the existing small opening to the vessel and expanding the heat exchanger framework to fill the vessel.

Background

Most vessels that contain heat transfer units were fabricated around the heat transfer unit. However, when heating and/or cooling is needed within an existing sealed vessel, the heat transfer unit typically fits into one of three categories:

- Large heat exchanger units around which the vessel must be manufactured

- Sectional units that must be inserted into the vessel one portion at a time and then assembled within the vessel

- Small units that can be inserted into the vessel as a single unit, but have large heat transfer paths to affect the entire vessel volume

Unlike most existing heat exchanger units, the expandable in-tank heat exchanger unit being designed at SRNL would be large enough (once deployed within the vessel) to provide heating, cooling, and/or measurements throughout the vessel while still being small enough to be inserted into a finished prefabricated vessel as a single unit.

Tank liner

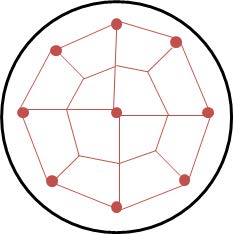

Tank liner cross-section

At a glance

- “Ship-in-a-bottle” in-tank heat exchanger

- Can be placed in a prefabricated vessel

- Can slide through a small diameter hole

- Can provide in-tank heating, cooling and measurements

- Minimizes heat transfer paths

Stage of Development

This technology is in the conceptual stage of the design process. It is application dependent (overall size, material selection, heating/cooling element(s) and/or data acquisition sensor placement, etc.).

Partnering Opportunities

SRNL invites interested companies with proven capabilities in this area of expertise to develop commercial applications for this process or product under a cooperative research and development agreement (CRADA) or licensing agreement. Companies interested in licensing will be requested to submit a business plan setting forth company qualifications, strategies, activities, and milestones for commercializing this invention. Qualifications should include past experience at bringing similar products to market, reasonable schedule for product launch, sufficient manufacturing capacity, established distribution networks, and evidence of sufficient financial resources for product development and launch.

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov