Tech Briefs

Savannah River National Laboratory

Vapor Phase Elemental Sulfur Amendment for Sequestering Mercury in Contaminated Soil

Scientists at the Savannah River National Laboratory (SRNL) have identified a method of targeting mercury in contaminated soil zone by use of sulfur vapor heated gas.

Background

Mercury contamination in soil is a common problem in the environment. The most common treatment is excavation – a method that works well for small sites where the mercury contamination is shallow. Other methods of treating mercury contaminated sites include high temperature soil vapor extraction to remove mercury and deployment of treatment materials in closely spaced boreholes to isolate mercury as it diffuses through the system. SRNL has developed an improved remediation method to distribute elemental sulfur into contaminated soil to treat elemental mercury. Elemental mercury reacts with the sulfur to form stable compounds with low solubility and low toxicity. Because gases move easily in soil, gaseous delivery of a chemical reagent is a preferred enhancement for many in situ treatment processes.

At a glance

- Eliminates excavation expense

- Applicable to large or small sites

- Straightforward deployment

- Uses heat to distribute sulfur throughout a soil

- Mercury reacts with sulfur to form immobile and insoluble minerals

- U.S. Patent 8,770,891 B2

How it works

This process uses elevated temperature and gas delivery to distribute significant quantities of sulfur throughout a treatment zone (without the need to inject liquids). For sites with small mercury inventories, the proposed method would be less expensive than baseline excavation. When coupled to high temperature soil vapor extraction (sites with large mercury inventories), the process would provide a significant added value for the investment in heating the subsurface and provide a basis for shutting off systems and limiting the time required for expensive heating.

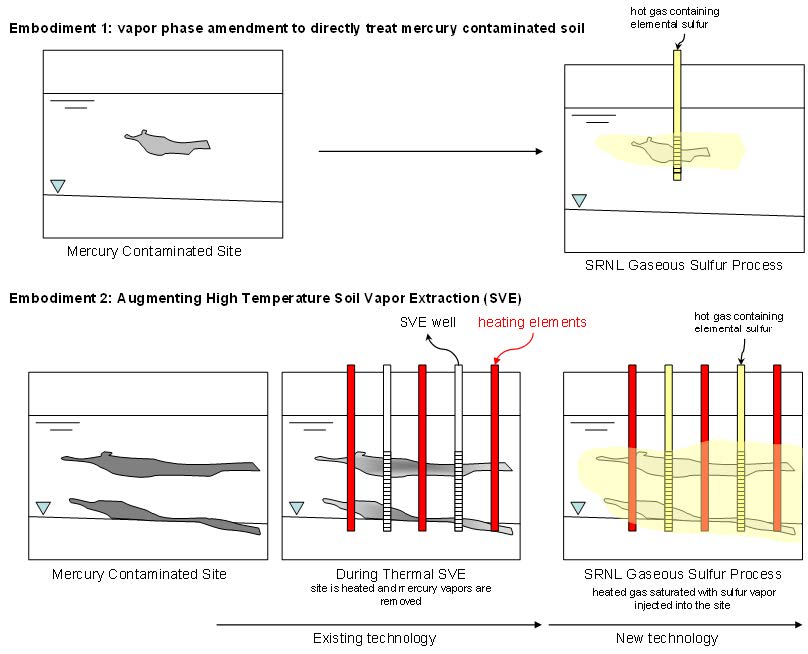

Direct treatment

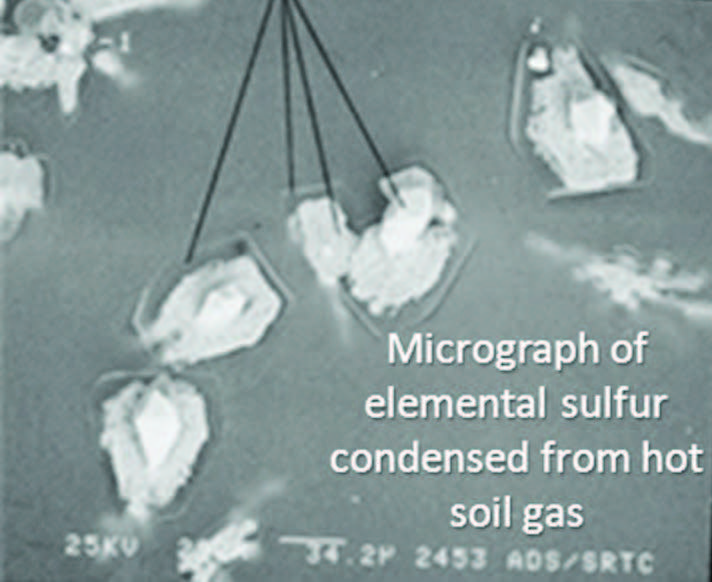

For sites that contain small quantities of mercury, process would include injecting the sulfur vapor saturated heated gas into access wells to distribute the gas throughout the site. Solid sulfur will precipitate in the cool soil, react with mercury and leave a residual phase to maintain conditions that limit mercury mobility/availability.

Augment high temperature soil vapor extraction

Recently, soil remediation methods have been developed to remove elemental mercury contamination from soil using high temperature (circa 250C) vapor extraction processes; high temperature heating elements and simultaneous pumping to remove gases containing volatized mercury from contaminated soil. The augmentation would be applied after the bulk mercury removal is complete and sulfur will chemically combine with and sequester, the remaining mercury in a nontoxic and stable mineral form. This technology would take advantage of high temperature created during the active extraction process to distribute significant quantities of sulfur throughout the treatment zone (without the need to inject liquid/fluids).

Partnering Opportunities

SRNL invites interested companies with proven capabilities in this area of expertise to develop commercial applications for this process under a cooperative research and development agreement (CRADA) or licensing agreement. Interested companies will be requested to submit a business plan setting forth company qualifications, strategies, activities, and milestones for commercializing this invention. Qualifications should include past experience at bringing similar products to market, reasonable schedule for product launch, sufficient manufacturing capacity, established distribution networks, and evidence of sufficient financial resources for product development and launch.

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov