Tech Briefs

Savannah River National Laboratory

Replaceable Ultrasonic Thickness/Mass Loss Measurement Coupon

Savannah River National Laboratory has developed a replaceable coupon that provides both high resolution ultrasonic thickness (UT) and mass loss measurements of erosion and corrosion in critical locations throughout a process system without disrupting the process flow stream.

Description

Incorporating mass loss as well as high-resolution UT measurement capability in a single device provides more sensitive measures of wear than conventional systems or systems providing high-resolution UT measurements alone. In addition, the unique size and design allow installation in vulnerable locations in a process system to provide timely information about the condition of the actively operating system. Because it can be used in an actively operating system, this device can dramatically reduce large-scale testing costs.

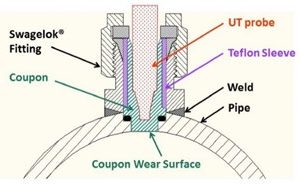

The coupon can provide in situ high-resolution UT measurements in most locations (piping, tanks, ducts, injection points, etc.) in a process system, including those with different pipe sizes/wall thicknesses. The design is optimized to allow accurate placement of a high-resolution UT pencil probe, which provides repeatable and more precise real-time wear data. This innovative design provides a means to evaluate critical evidence of corrosion and erosion without significantly disrupting the process flow stream.

The coupon can also be removed periodically to nondestructively evaluate mass loss as well as surface features resulting from corrosion (general and localized) and erosion. Once the coupon is removed, mass loss can be verified by independent techniques, such as ultrasonic and conventional micrometer measurement. An optical microscope or scanning electron microscope can be used to investigate active corrosion mechanisms, such as pitting and crevice corrosion. Finally, scar depth and orientation can be accurately evaluated using a surface profilometer or a laser confocal microscope.

Schematic showing coupon installed in a pipe.

Benefits

- More sensitive than conventional or high-resolution-UT-only systems

- Shortens test duration, reducing large-scale test costs (simulant, operations, etc.)

- Minimizes process flow stream disruption

- Provides a correlation between UT and mass loss data

- Provides quantifiable data on erosion patterns, scar depth and pit morphology

Applications and Industries

- Corrosion coupon providers (Metals Samples)

- Corrosion Test Laboratories (DNV GL Labs and National Labs)

- End users such as oil and gas industry and chemical industry

Removable Ultrasonic Thickness/Mass Loss Coupon

UT probe inserted into a coupon installed in the extradose of a 3 inch, schedule 40, 90 degree stainless elbow

Intellectual Property

- US Patent SRNS-99 (SRS-16-013 and 12-027)

- Testing underway at Florida International University (supporting Hanford Tank Farm)

- Custom as-required

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov