“The projects…will leverage SRNL’s expertise in fusion fuel cycle technologies in unique ways to help design and implement improved systems in significantly different fusion concepts.” – Brenda Garcia-Diaz, SRNL Fusion Energy Research Program Manager

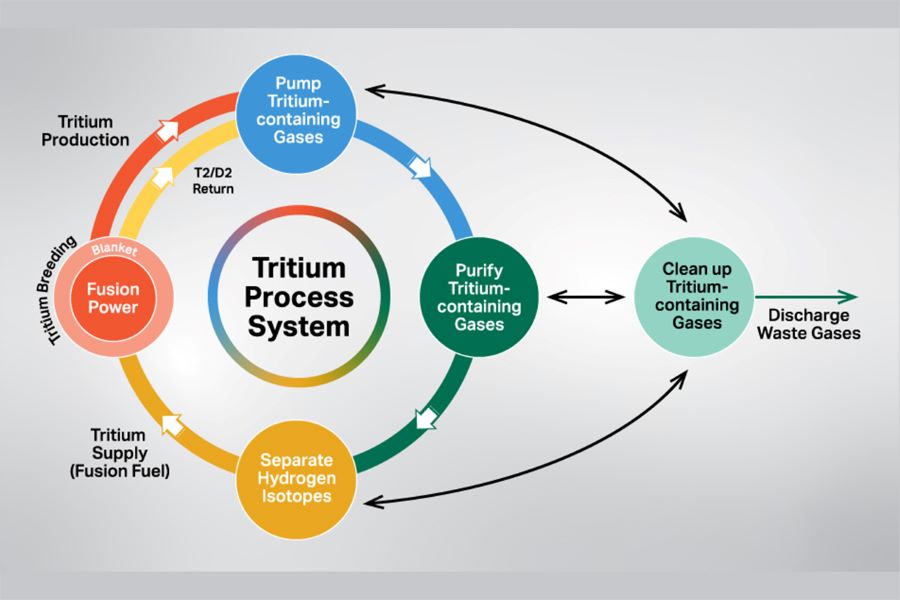

An overview of SRNL’s vision for the fusion fuel cycle. The fuel cycle breeds new tritium and recovers unburned tritium, purifies it,

and prepares it to be fed back into the reactor, creating a safer, more efficient fuel cycle. graphic: Savannah River National Laboratory

For a commercially viable fusion energy plant, research, design and development is needed to create an efficient, continuously operational fuel cycle. That’s where SRNL’s expertise comes in.

Savannah River National Laboratory is working to advance technologies, materials, and process efficiencies to help realize fusion energy commercialization. Initial commercialization of fusion energy expects to use a deuterium-tritium fuel cycle. SRNL is the nation’s leading laboratory in tritium science and engineering, with more than 60 years of success in supporting the National Nuclear Safety Administration (NNSA) Defense Program mission for tritium supply. SRNL is currently focused on five tritium research topics relating to the fusion fuel cycle:

- Process Modeling, Process Control and Simulation

- Defining models to advance and optimize system design, monitor operation, control the process and simulate performance during operation.

- Tritium Inventory Reduction and Improved Process Technologies

- Improving tritium processing to reduce the inventory needed and lower the radioactive source term.

- Isotope Supply, Tritium Breeding, and Tritium Extraction

- Defining tritium/isotope supply source and processing, ensuring the tritium breeding ratio is achievable, and minimizing captive inventory

- Tritium Confinement to Reduce Emissions and Support Safety Basis

- Developing advanced tritium wetted materials and confinement barriers, understanding and mitigating tritium effects on plasma-facing components, and improving tritium removal and recovery from secondary/ tertiary confinements and effluent streams.

- Tritium Accountability and Tritium Analytical/ Diagnostic Capabilities

- Developing rapid, high-accuracy/precise accountability measurement instruments and techniques to measure tritium and account for it in different parts of the system.

SRNL is applying its tritium expertise to advance fusion energy projects and research and development investigations with ITER (formerly known as International Thermonuclear Experimental Reactor) and other Fusion Energy Sciences (FES) and Advanced Research Projects Agency – Energy (ARPA-E) programs.

Within the U.S. ITER program, SRNL is leading the design, construction, and testing of the Tokamak Exhaust Processing system. For a commercially viable fusion energy plant, research, design and development is needed to create an efficient, continuously operational fuel cycle that can breed and extract tritium; exhaust byproduct helium; remove and exhaust impurities; separate and rebalance hydrogen isotope mixtures; and provide fuel to the fusion machine.

The deuterium-tritium fusion fuel cycle applies to both magnetically confined fusion energy (MFE) and inertially confined fusion energy (IFE) concepts. Both magnetically and inertially confined fusion energy require structural and process system materials that are durable in extreme environments. Current and near-future research, design and development investigations at SRNL include:

- Exploring methods to implement direct internal recycling of hydrogen isotopes with an MFE system.

- Improving all fuel cycle stages (tritium extraction, impurity removal, isotope separation, and fueling) to have higher throughput with lower tritium inventory.

- Developing and characterizing durable materials exposed to hydrogen, deuterium and tritium.

- Improving pumping technologies for hydrogen isotopes and helium.

- Process modeling with gap analysis to identify technology needs and optimize process design including minimizing tritium inventory.

- Developing technologies to minimize environmental release of tritium through permeation barriers, water detritiation, and other methods of tritium containment and recovery.

INFUSE Awards – Public-Private Partnerships

SRNL works with the Department of Energy (DOE) to support fusion commercialization through partnerships with companies that are developing fusion plants and implementing fusion fuel cycles. SRNL also has capabilities to support fusion device design-build with technologies for fabricating system components by advanced manufacturing; robotics for remote maintenance; system modeling and control using artificial intelligence; and other areas needed for developing a functional fusion plant. SRNL engages companies through public-private partnership (PPP) programs such as INFUSE that will help solve technology challenges and enable the commercialization of fusion energy.

Sponsored by the Fusion Energy Sciences (FES) program office within DOE’s Office of Science, Innovation Network for Fusion Energy, the INFUSE program focuses on accelerating fusion energy development through public-private research partnerships. SRNL received two Department of Energy (DOE) INFUSE awards with General Atomics and General Fusion to further advance the fusion fuel cycle and development of a commercial fusion power plant.

“These two new INFUSE awards continue SRNL’s efforts to deepen industry engagement through public/ private partnerships that help industry develop their technologies into viable commercial solutions,” said SRNL Fusion Energy Research Program Manager Brenda Garcia-Diaz. “The projects with General Atomics and General Fusion will leverage SRNL’s expertise in fusion fuel cycle technologies in unique ways to help design and implement improved systems in significantly different fusion concepts.”

General Atomics is developing a modeling workflow for fusion pilot plant (FPP) integrated design and optimization, and needs verified and validated models for the tritium fuel cycle. SRNL will develop two models for General Atomics’ use: a reduced model for tritium processing, which will be utilized by General Atomics’ FPP systems code, as well as comprehensive Aspen fuel cycle simulations to assess the significance of design decisions. General Atomics and SRNL will perform FPP optimizations with these tools and SRNL will supply a relative, initial cost analysis for the tritium processing facilities. General Atomics Principal Investigator David Weisberg and SRNL scientist Holly Flynn are leading this project.

“One of the most attractive aspects of a fusion power plant is the environmentally friendly hydrogen fuel, which doesn’t require any harmful mining or drilling activities,” explains David Weisberg. “But we also need to perfect the way we recycle fuel inside the power plant, and SRNL has expertise to advance the technological readiness of that system.”

With General Fusion, SRNL will work to model the total inventory of tritium in General Fusion’s future commercial pilot plant (CPP) design. Understanding tritium inventory is a necessary step to design, license, construct, and operate larger and increasingly integrated fusion machines.

With General Fusion, SRNL will work to model the total inventory of tritium in General Fusion’s future commercial pilot plant (CPP) design. Understanding tritium inventory is a necessary step to design, license, construct, and operate larger and increasingly integrated fusion machines. SRNL will apply its expertise to quantify and streamline tritium processing in the CPP to support General Fusion’s pilot plant development to deliver clean, safe, and on-demand fusion power at commercial scale. General Fusion Chief Technology Officer Ryan Guerrero and SRNL Scientist George Larsen are leading this project.

“General Fusion’s practical Magnetized Target Fusion technology is designed with a low start-up tritium fuel requirement and an advantageous breeding ratio to produce sufficient quantities of tritium fuel to sustain the fusion process,” said General Fusion Chief Technology Officer Ryan Guerrero.

A third INFUSE award has SRNL partnering with Commonwealth Fusion Systems to investigate molten salt as a novel blanket material for its fusion tokamak. But molten salt made from a mixture of lithium fluoride (LiF) and beryllium fluoride (BeF2) FL:Be is known to cause significant degradation to structural materials. Use of FL:Be for commercial fusion applications requires applying corrosion mitigation strategies. Commonwealth Fusion Systems is leveraging SRNL’s expertise in electrochemical and corrosion engineering to monitor corrosion caused by FL:Be in real time, and to enable local control of corrosion rates by adjusting impurity concentrations in FL:Be.

University Partnerships

SRNL is also working with university and workforce development partners on fusion projects, most notably with its BSRA university partners – the University of South Carolina, Georgia Tech, South Carolina State University, The University of Georgia, and Clemson University. Through the Galvanizing Advances in Market-aligned fusion for an Overabundance of Watts (GAMOW) program, SRNL is creating novel solutions that can simplify fuel-cycle processes and reduce equipment cost, as well as provide more efficient solutions that reduce energy and other resource input (e.g., liquid nitrogen) costs.

Two examples of these fusion projects include working with Clemson and the University of South Carolina on the Hydrocarbon Pump Oil Recycling (HyPOR) Loop and the Direct LiT Electrolysis. The HyPOR Loop uses a process to enable the use of commercially available vacuum pumps in the fuel cycle that will reduce costs, improve safety and make the process more energy efficient. The Direct LiT Electrolysis leverages advances in Liion battery materials, adapting them to simplify tritium fuel-generation steps to increase efficiency and safety and reduce costs.

SRNL also collaborates with colleges and universities nation-wide such as the Massachusetts Institute of Technology, NC State, and others to help advance tritium processing and fusion fuel cycle technologies through programs with both the DOE and National Nuclear Security Administration (NNSA) that help to advance both fusion and national security programs. In addition, SRNL is leveraging relationships with minority serving institutions that it developed through managing the minority serving institutions partnership program (MSIPP) for DOE EM. SRNL will work also to incorporate energy justice principles for fusion into regulation development, public engagement, workforce development, and other aspects of fusion commercialization.

Other Fusion Research at SRNL

SRNL is active in other areas of fusion research, including Deactivation & Decommissioning, regulation, and non-proliferation. Tritium in fusion waste materials could prevent near surface burial, which is the desired disposal route for fusion waste. Non-proliferation concerns have generated significant discussion and SRNL is engaging with the U.S. and international fusion communities on this issue. Because of the importance of these topics to the future of fusion energy, research at SRNL involves all three research directorates within SRNL – Environmental Management and Legacy Management, Global Security and Weapons Production Technology

Fusion Demonstration Facilities at Savannah River Site

In addition to leveraging years of experience working with tritium, the unique resources at the Savannah River Site (SRS) can help advance the commercialization of fusion energy by locating demonstration facilities or siting fusion plants at SRS. Advantages of locating a fusion facility at the site include staying within preapproved tritium inventory amounts, exceptional site characteristics, and having defined environmental analyses.

Savannah River Site Advantages

Well Characterized Site

SRS covers approximately 198,000 acres (310 square miles) adjacent to the Savannah River in Aiken, Barnwell and Allendale counties of South Carolina. Facilities account for approximately only 5% of the SRS area; apart from facilities, land cover is a wide variety of natural vegetation types and the land available is well-suited for siting a plant.

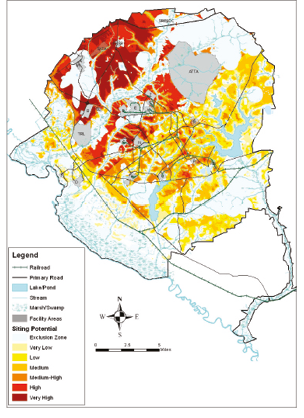

Mature Site Selection

SRS has a mature and systematic site selection process that was developed by SRNL, and which dates to 1990 with the comprehensive evaluation in the siting for a new production reactor. Based on ranking the siting requirements for the proposed facility, this process uses a team approach and GIS technology to identify specific site locations at SRS for new facilities. Based on site requirements and ranking the requirements, the best places for a proposed facility can be seen in the graphic at left – red meaning the best places for a facility at SRS.

Transportation and Utilities

Locations can be identified at SRS that have access to cooling water, grid access, rail and barge transportation, grid interconnection, and access to publicly accessible roads, all of the things needed to build and maintain a proposed fusion plant.

Tritium Research, Development & Demonstration (RD&D) Facility

SRNL is investigating the creation of a tritium research, development and demonstration facility for tritium processing technologies with an unused building on site that was descoped from a previous project. The facility would:

- Create a Category 2 nuclear facility that could enable tritium RD&D with inventories up to 1 kilogram.

- Yield ~8000 sq. ft. or 30% of the available space for a fusion fuel cycle demonstration facility.

- Leverage research and testing capabilities for NNSA missions, advancing both national security and fusion energy.