Tech Briefs

Savannah River National Laboratory

Reductive Precipitation for Technetium Removal from Salt Waste

Researchers at the Savannah River National Laboratory (SRNL) have discovered a precipitation method for removing technetium from highly alkaline nuclear waste liquid.

Background

Significant soluble technetium removal from highly alkaline solutions was found to be a difficult region for inorganic precipitation processes. Such removal would be of value for future nuclear liquid processing, among other applications. Past work considered iron adsorbents and also chemicals containing tin, but none found conditions that create a strong technetium removal at a high rate. Both high alkalinity and ambient oxygen present challenges to removal of pertechnetate by precipitation processes. However, tin (ll) (stannous ion) was a reductant that is known to effectively reduce pertechnetate in solution. It is effective in removing pertechnetate if the solution is not very alkaline.

At a glance

- Works in high alkaline solutions

- Likely to remove other waste isotopes

- Useful for nuclear cleanup

- U. S. Patent 9,388,478 B1

A New Solution for the Future

This method of technetium removal combines inorganic chemicals to precipitate solids in 6M sodium, pH 14 solution. Order of reagent addition was found to be significant. This causes rapid and significant adsorption of technetium that was in the solution as pertechnetate. Such a process can be used in a process vessel where precipitate is formed, mixed, and filtered, with the liquid filtrate having reduced technetium content. Bench scale lab testing was performed at room temperature with no effort to remove ambient oxygen that is present in the air. The work found that phase pure magnetite powder adsorbed technetium slowly but measurably for the same caustic solution.

SRS will be processing waste with higher technetium-99 (waste isotope) concentrations in the future. Currently the Site does not have any waste separation process for technetium and much of that fission product goes to the Saltstone facility. This technology could be applied with relatively little work in a waste filter plant to reduce the amount of technetium-99 in the waste that flows through.

This invention is most specific to nuclear waste since medical and radiochemical activities often avoid the high sodium, highly alkaline condition that characterizes millions of gallons of nuclear waste. This invention may also be useful to Hanford, another processor of highly alkaline liquids containing technetium-99.

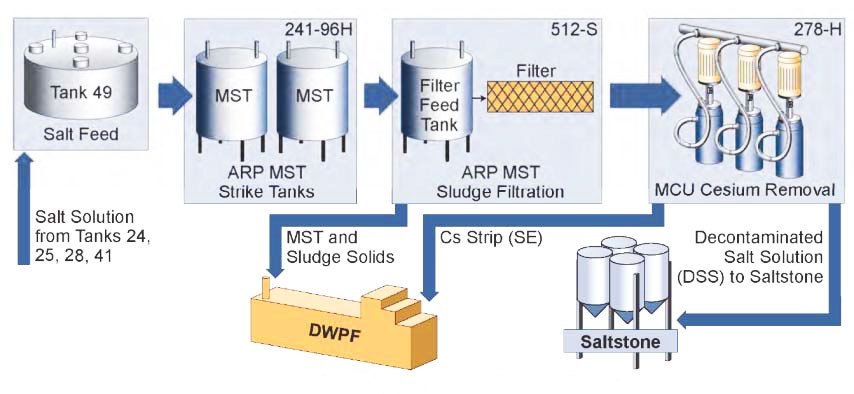

Example of an addition, mix, and filter batch system: The SRS Actinide Removal Project

Stage of Development

This technology has been bench scale tested. A patent has been filed with the U.S. Patent and Trademark Office.

Partnering Opportunities

SRNL invites interested companies with proven capabilities in this area of expertise to develop commercial applications for this process under a cooperative research and development agreement (CRADA) or licensing agreement. Companies interested in licensing will be requested to submit a business plan setting forth company qualifications, strategies, activities, and milestones for commercializing this invention. Qualifications should include past experience at bringing similar products to market, reasonable schedule for product launch, sufficient manufacturing capacity, established distribution networks, and evidence of sufficient financial resources for product development and launch.

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov