Tech Briefs

Savannah River National Laboratory

Integrated Onboard Vehicle Natural Gas Storage Heating and Cooling System

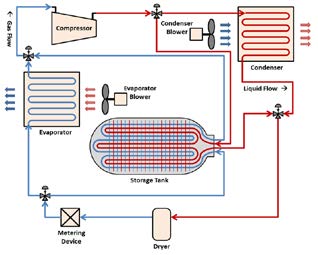

Savannah River National Laboratory has developed an integrated natural gas storage heating/cooling scheme that connects a vehicle’s existing onboard heat-exchanger fluids to an adsorbent natural gas system to provide temperature swing capabilities to maximize the system’s gas storage capacity.

Need

Mass, volume, and cost are obstacles to designing new vehicle technologies to compete with gasoline/diesel internal combustion engines. Adapting an internal combustion engine to run on less expensive and lower emission natural gas, for example, can actually increase a vehicle’s mass, volume, and cost because natural gas currently requires greater storage capacity than a gasoline/diesel tank, necessitating modifications to a vehicle’s framework. Natural gas is normally stored on motor vehicles in high pressure tanks that use changes in pressure to charge and discharge the gas.

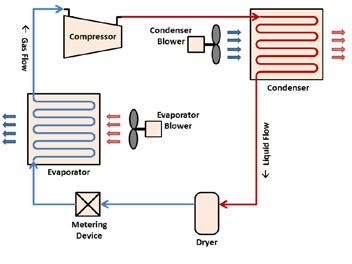

Standard automotive air conditioning system diagram.

Automotive air conditioning schematic for a thermal fluid by-pass to an absorbent storage vessel to heat or cool the vessel in place of the condenser or evaporator, respectively.

Benefits

- Uses temperature-assisted pressure swing to store more gas in a smaller volume

- Utilizes heat transfer systems already on a vehicle to control the gas temperature:

– Radiator fluid and/or air conditioning coolant for heating (needed to maintain pressure and assist in gas release from absorbents)

– Air conditioning coolant for cooling (primarily for refueling)

- Avoids the heat issues of conventional compressed gas storage

Applications and Industries

- Most applicable to automotive industry and other commercial markets that utilize (or plan to use) mobile gas storage (e.g., in forklifts, heavy machinery, and portable generators)

- Could also be useful in stationary gas storage vessels needing both heating and cooling utilities

Description

SRNL’s integrated gas storage heating/cooling scheme connects the existing onboard heat exchanger fluids (with some possible augmentation) to an adsorbent such as activated carbon or a metal-organic framework. With this design, the same amount of natural gas can be stored in a volume comparable to current gasoline/diesel tanks at a lower pressure than conventional natural gas storage, which also reduces both cost and mass. In addition, by using the onboard heat exchanger fluids, SRNL’s integrated gas storage heating/cooling scheme also avoids the heat issues that plague conventional compressed gas storage.

Intellectual Property

- Divisional patent based on US 9,683,704 B2 issued on 20 June 2017.

- Technology Readiness Level (TRL) 2 or 3:

– Basic system models created

– Finite element analysis (FEA) models of several adsorbent tanks with internal heat exchangers created

– Lab-scale prototype heat exchanger system built and demonstrated for hydrogen

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov