Tech Briefs

Savannah River National Laboratory

High Temperature Thermochemical Energy Storage

Technology Overview

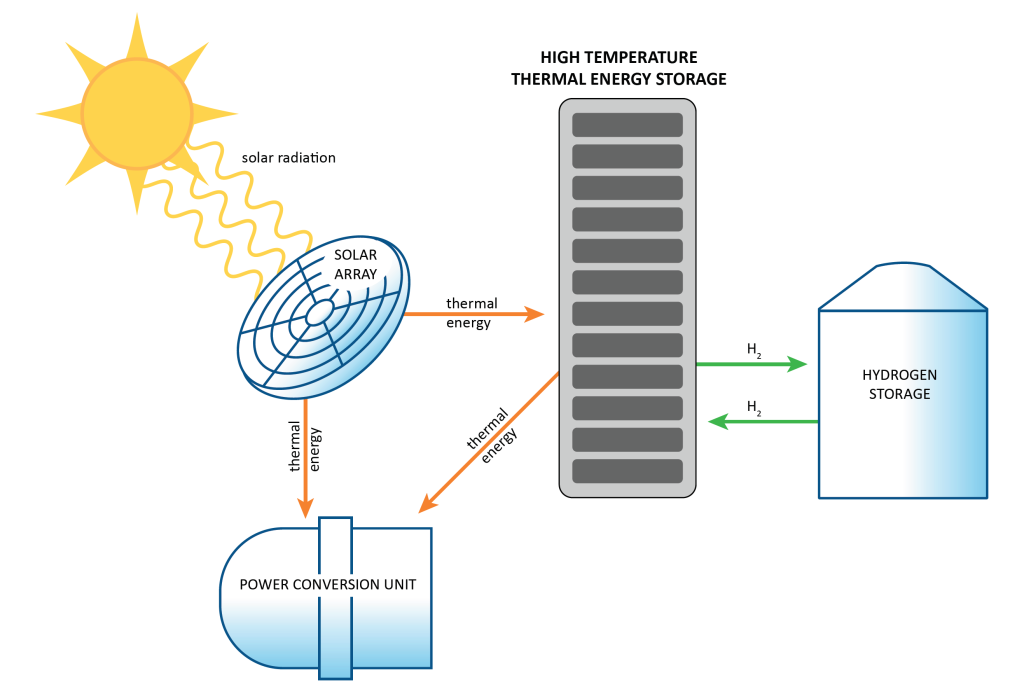

Savannah River National Laboratory has developed a novel thermochemical energy storage material from Earth abundant elements that provides long-duration energy storage solutions for high temperature power conversion technologies. This material was strategically designed to operate at temperatures from 600°C to 800°C to power high efficiency, thermal-to-electric power conversion units such as Stirling engines. Thermal energy is stored in chemical bonds in a solid-gas system in which the gas reactant can be separated and stored for later use. Specifically, when the material is heated, hydrogen is released, separated, and stored. At a later time, the hydrogen is allowed to react with this material to generate heat for the desired application.

Illustration of thermochemical energy storage in metal hyride technology using concentrated solar power thermal input.

Benefits

- High temperature operational capability

- Higher gravimetric and volumetric energy densities than sensible and latent heat materials

- Long-duration energy storage and seasonal storage capable

- Low-cost material made from earth abundant elements (e.g., calcium, aluminum, and silicon)

Applications and Industries

- Thermal energy storage for concentrated solar power

- Thermal energy storage for niche grid storage applications

- Long duration energy storage

- Residential combined heat and power applications

Description

This innovative material solves challenges associated with high temperature thermal energy storage. Many molten salts suffer from corrosion and decomposition challenges at temperatures greater than 550 °C. This technology is noncorrosive, and is designed to operate at high temperatures that provide increased efficiency from the thermal-to-electric power conversion unit. Additionally, this material has an energy density nearly an order of magnitude greater than most sensible heat materials and possesses thermal conductivities far greater than many of the molten salt technologies. This provides a thermal energy storage platform that is substantially smaller, operates at high temperatures, and consists of highly abundant materials.

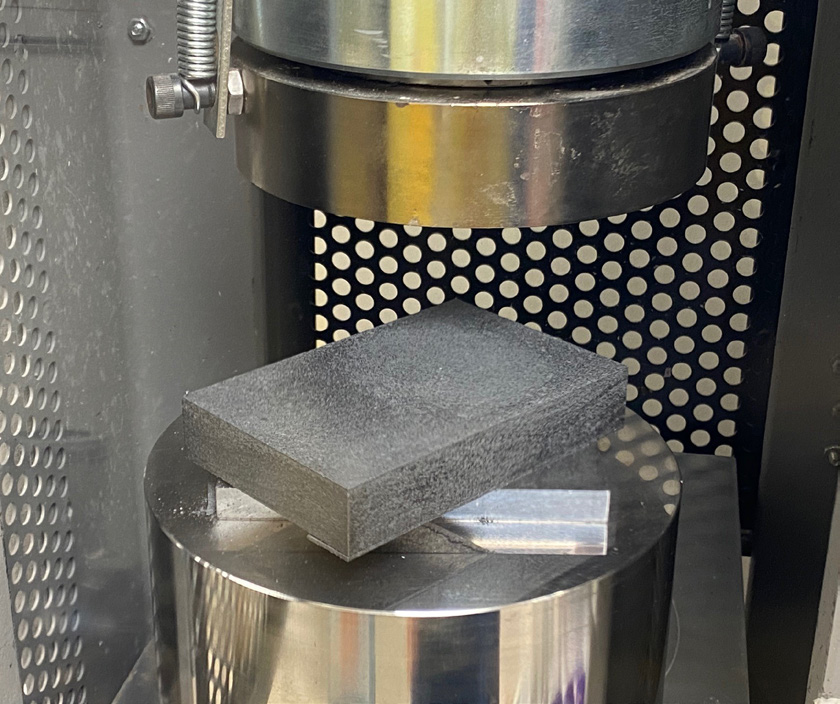

Stacked blocks of thermochemical storage material in a heat exchanger test bed.

Intellectual Property

- Ward, P. A.; Zidan, R. High Temperature Thermochemical Energy Storage Materials Filed: April 28th, 2022, US 2022/0128270.

- Material produced at the multi-kilogram level and demonstrated in a 2 kWhth storage system coupled with super critical CO2 heat exchanger.

Compression of powdered thermochemical energy storage material with thermal conductivity enhancement additives.

Partnering Opportunities

SRNL invites interested companies with proven capabilities in this area of expertise to develop commercial applications for this process under a cooperative research and development agreement (CRADA) or licensing agreement. Interested companies will be requested to submit a business plan setting forth company qualifications, strategies, activities, and milestones for commercializing this invention. Qualifications should include past experience at bringing similar products to market, reason-able schedule for product launch, sufficient manufacturing capacity, established distribution networks, and evidence of sufficient financial resources for product development and launch.

Download Tech Brief

Contact Information

Savannah River National Laboratory

E-mail: partnerships@srnl.doe.gov